What's LaSIE?

What's LaSIE? |

News

News |

Research Topics

Research Topics |

People

People |

Publications

Publications |

Seminars

Seminars |

Member's Area

Member's Area | |

|

Laboratory for Scientific Instrumentation and Engineering

|

|

|

|

||||||||

| Research topics in LaSIE | » Back to Research page |

|

Micro/nano laser fabrication by two-photon initiated photopolymerization | |

|

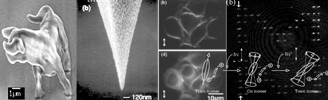

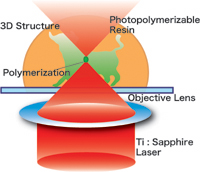

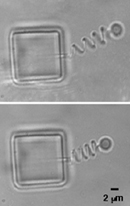

Introduction Two-photon absorption (TPA) provides the ability to confine photo chemical and physical reactions to the order of laser wavelength in three dimensions. For applying TPA to laser precision fabrication, we have proposed a two-photon initiated photopolymerization technique. The diffraction limit can be exceeded by nonlinear laser-matter interaction processes, and spatial resolutions far smaller than the diffraction limit are achieved. Three-dimensional fabrication by two-photon initiated photopolymerization A mode-locked Ti : Sapphire laser (780 nm, 82 MHz, 80 fs) was utilized as the exposure source. The laser beam was focused into a photopolymerizable resin by an objective lens (N.A. = 1.4). Since the resin is transparent in infrared wavelength, the solidification of the resin occurs only at the close vicinity of the focal point by simultaneously absorbing two photons (Fig. 1). By scanning the focal point according to a pre-programed pattern, desired three-dimensional structures can be formed following the scanning trace. A set of two galvanometer mirrors and a piezo stage were used for scanning the laser spot in x-y and z direction, respectively. After removing the unsolidified resin with ethanol, the fabricated structure was observed by a scanning electron microscope (SEM). The size of solidified voxels was reduced because of the quadratic dependence of TPA probability on the incident light intensity. Furthermore, photogenerated radicals in this volume were subject to scavenging by dissolved oxygen molecules, so polymerization reaction was not initiated and propagated if the exposure energy was less than a critical value. These nonlinear effects gave spatial resolution of 120 nm. Fig. 2 shows SEM image of a micro-bull sculpture. The 8 µm long, 7 µm high bulls are the smallest animals ever made artificially, and are as small as the red blood cell. Device functionalization We have applied this technology to produce functional micro devices. We fabricated a micro-spring with spiral diameter of 300 nm shown in Fig. 3. For device driving, the laser trapping force was adopted. To employ the laser trapping as a driving force, a micro bead with diameter of 3µn;m was polymerized at one end of the spring. The other end was fixed to an anchor that was polymerized on the substrate. It was clearly observed that the bead was trapped in three dimensions. Correspondingly the spring was prolonged, compressed and bent. When released from an extended state by shuttered off the laser power, the spring was gradually restored its original length. References

» Back to Research page |

Fig.1 Two-photon initiated photopolymerization for three-dimensional fabrication. 3D scanning of polymerization spot makes 3D structure with nanometer-order precision.  Fig.2 SEM image of a micro-bull sculpture.  Fig.3 Elastic deformation of a micro-spring. The spring was kept in ethanol. |